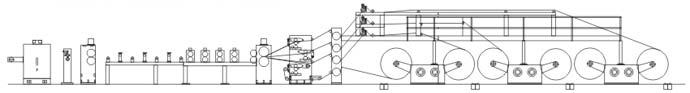

1200-2200硬纸板生产线

发布时间:2017-05-24 14:59:37

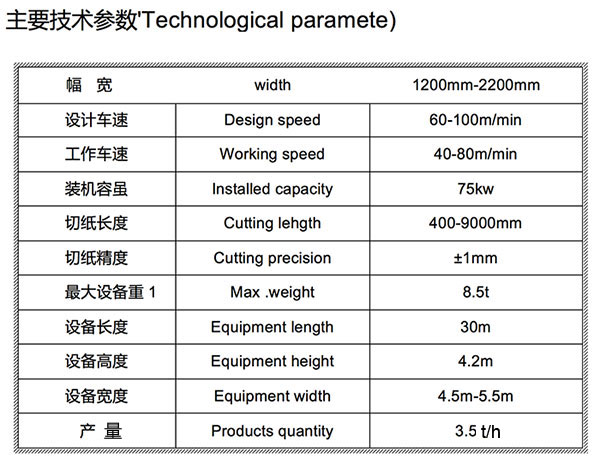

功能特点: 硬纸板生产线适用于将2-4层的300-600g/米2进行复合。主要由承纸架、过桥输送机、涂胶机、压实 机、(平板式)烘干部、冷却部、分纸牵引机、电脑横切机、堆码机等组成,具有生产工艺先进、操作维 修方便、安全可靠、节约能源、无环境污染等特点〇生产线采用卷筒纸复合,幅宽有1200mm~2200mm等 规格供您选择,可将三张、四张原纸进行复合,定量2000g/m2、厚度3.5mm、产量35T-80T/d,该线生产 出的纸板厚度、紧度、水份、平滑度、挺度、抗张强度均达到进口的同类产品,完全可以替代进口的超厚 硬纸板,该产品适用于烟箱、酒箱、箱包、食品箱、精装书皮、高档礼品盒、文具用品等。该生产线弥补了 单机手工裱糊的多项缺点,大幅度降低了生产成本、提高了产品质量、经济效益可观,是您制作硬纸板及 硬纸板箱的理想设备。

The carton board production line applys to laminating 2-4 ply materia! weight of 300-600g/ m2〇 The machine is composed mainly of stand, bridge conveyor, gluer, compactor press,(platform) dryer, cooler, thin blade slitter scorer, CNC cutting machine and stacker. With characteristics of advanced production engineering, easy operation and maintenance,safe and steady, energy saving and environment friendly. Size 1200mm~2200mm are optional, quantified 2000g/m2, thickness 3.5mm, through put 35T-80T/D. The the thickness, tightness, moisture content, smoothness, stiffness and tensile strength can reach the standard of the imported products. Which can eventually replace the imported corrugated board, which suit for the cigarette box, wine box, food box, hard book cover, High-end gift box and stationery. The production line makes up for many defects of the manual laminator,greatly reduced the cost of production, improved the quality of production, increased the economic efficiency. It is your ideal choice to product corrugated board and carton boxes.

|

SY型四层预热器 SY type 4 ply pre-heater ♦预热器可根据纸板干湿程度加热调整石英管温度,增加纸张 平整度。 ♦热辊的表面经过磨削并镀硬鉻,热辊表面的温度均匀一致, 使其达到原纸在进入涂胶机前的温度基本一致。 ♦ The temperature of quartz tube of pre-heater can be adjusted according to the moisture content of paper, increasing the smoothness of the paper. ♦ The heating roller is surface grinded and chrome covered, making even heating of the paper before it goes into the gluing machine. |

|

SD型对边机

SD type Alignment machine

♦该对边机有四层,每层有机架、导纸辊、纠偏器,汽油压控 制自动对边、对齐、自动校正纸张。

♦有效的保证纸张在涂胶时纸边对齐,减少纸张废品,提高生 产效率。

♦ This machine has 4 levels that each has stand, guiding roll, corrector, automatic oil pressure control aligning and automatic correcting of paper.

♦ It can guarantee the alignment of paper during gluing, reduce the waste products and increasing the production efficiency.

|

|

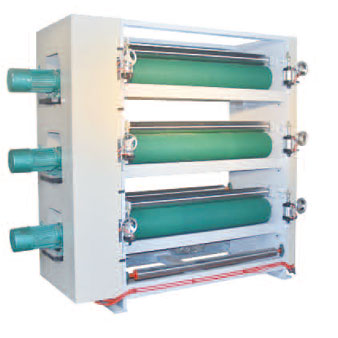

ST型三层涂胶机

ST type 3 ply gluing machine

♦涂胶机起到给原纸涂腔的作用。

♦每层涂腔单独传动,变频控制,保证上胶辊的线速与双靣机同步。 ♦匀胶辑表面经精磨、压网、镀鉻处理,。

♦涂腔辊为软胶辊,且M边有调整装置,使其涂腔均匀。压纸辑妥用气 动装置,操作更方便。

♦ The gluing machine is to glue on the material paper.

♦ Each gluing is independent driven, frequency controlled to guarantee the gluing roller keep the same speed to the double facer.

♦ the anilox gluing roller is surface grinded and chrome covered.

♦ The rubber gluing roll can be adjusted to make even gluing.

The guiding roll is pneumaticly control, convenience for operation.

|

|

YS-QD压实机

YS-QD Compacting machine

压实部是硬纸板生产线的一个重要组成部分,它 的主要用途是上辊和下辊将原纸和面纸压合成所需的 多层纸板。

The compacting machine is one of the important parts of carton board production line. It use the upper roll and lower roll to press the base paper and face paper to be multilevel carton board.

|

|

FZ-DY分纸机

FZ-DY Slitting machine

分纸机是硬纸板生产线的重要组成部分,它的主要 特点是将复合好的硬纸板进行纵切,刀片采用好9crsi 合成,刀锋锋利,使用寿命长,整机电动左右纠偏,有 效配合纸幅偏移。

The slitting machine is one of the important parts of carton board production line. It cuts the carton board in length way s.the cutting blade adopts 9CrSi alloy steel, with characteristic of sharp edge and long use time, the machine is electrically correct a error which can match with the shifting of carton board.

|

|

单刀切纸机 single-blade paper cutter ♦合理的机械结构,刚性强、稳定性好、使用寿命长; ♦所有操作控制在同一侧靣,操作方便,光电计数; ♦横切长度400-的99mm; ♦切纸精度± 1mm。 ♦ Rational mechanical structure, strong form, good stability, have long performance life. ♦ All operation control on the same side, easy to operate, with photoelectricity counter. ♦ crosscut 400mm-9999mm. ♦ Cut paper precision ± 1 mm. |